-

Structural Steel Fabrication

-

Heavy Steel Fabrication

-

Metal Steel Fabrication

-

Sheet Metal Fabrications

-

High Rise Steel Building Construction

-

Structural Steel Frame Construction

-

Steel Girder Bridge

-

Steel Truss Bridge

-

Pedestrian Overpass Bridge

-

Prefab Steel Frame

-

Light Steel Framing

-

Galvanized Steel Structure

-

Stainless Steel Fabrication

-

Steel Street Light Pole

-

Overhead Sign Structures

-

Steel Arch Bridges

-

Precast Girder Bridge

-

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job!

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job! -

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

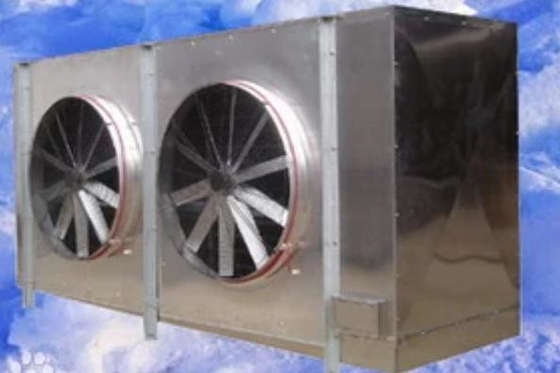

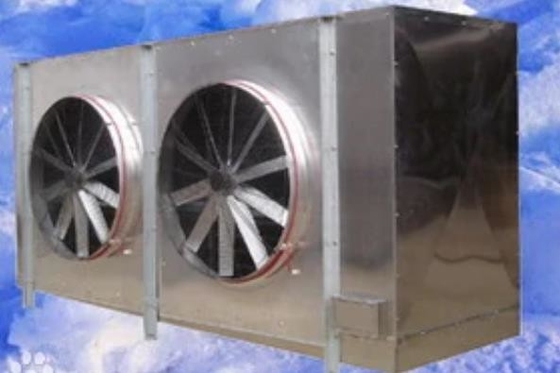

Stainless Metal Steel Fabrication Manufacturers Streamlined Air Cooled Heat Exchanger

| Place of Origin | Zhejiang China |

|---|---|

| Brand Name | FAMOUS-KNSN |

| Certification | ISO3834, AWS D1.1 and EN1090 etc |

| Model Number | Famous-Exchanger |

| Minimum Order Quantity | 1 set |

| Price | USD1500~USD3500 per ton |

| Packaging Details | Seaworthy framed packings for either container or break bulk vessel etc |

| Delivery Time | 2-5 months dependingly after final drawings confirmation |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 9000MT Per Month |

| Color | White Or Customized | Material | Normal Or Low Temperature Impacted Steels |

|---|---|---|---|

| Grade | ASTM A36, A572, SM490, Q355, Q235 Etc | Surface | Usually Hot Galvanized |

| Standard | US, Europe, Australia, UK Britain Etc. | Application | Oil & Gas Etc Fields |

| Highlight | stainless steel metal fabrication,stainless Metal steel fabrication FAMOUS-KNSN,stainless Metal steel fabrication manufacturers |

||

Streamlined System Air Cooled Heat Exchanger Engineering and Manufacturing Facility Metal Steel Fabrication

As the professional foreign standards metal fabricators, we are quite capable to fabricate various steamlined system air cooled exchanger steelworks based on either EU-US or UK AU etc standard and requirements.

The air cooled heat exchanger is referred to as an air cooler, which uses air as a coolant and can be used as a cooler or a condenser. The air cooler is mainly composed of tube bundles, brackets and fans. Air cooler hot fluid flows inside the tubes and air blows outside the tube bundle. Due to the large amount of ventilation required for heat exchange and the low wind pressure, axial fans are often used (see fluid conveying machinery). The type and material of the tube bundle have a great influence on the performance of the air cooler. Due to the small heat transfer coefficient on the air side, fins are often added to the tube to increase the heat transfer area and fluid turbulence and reduce thermal resistance.

Most air coolers use radial fins. In the air cooler, a light tube with an outer diameter of 25mm is usually used, a low fin tube with a fin height of 12.5mm, and a high fin tube with a fin height of 16mm. The fins are generally made of a material with high thermal conductivity (the most common is aluminum), and are wound or inlaid onto the light pipe. In order to strengthen the heat transfer effect of the air cooler, water can be sprayed in the inlet air to humidify. This not only reduces the air temperature, but also increases the heat transfer coefficient. The use of air coolers can save a lot of industrial water, reduce environmental pollution, and reduce infrastructure costs. Especially in water-deficient areas, replacing water-cooling with air-cooling can alleviate the contradiction of water shortage.

|

Model

|

Capacity Kw

|

area m2

|

Fan | Pipe Dia(mm) | Overoll size (mm) | installation size (mm) | |||||||||

|

Fon input (w) |

Dia. (mm) |

Volt (v) |

Air flow m3/h | in | out | A | B | C | a | al | b | ||||

| FAS-72 | 21.5 | 72 | 1x600 | 380 | 7950 | 2x(p22 | 2xcpl6 | 940 | 980 | 880 | 740 | / | 900 | ||

| FAS-111 | 33.5 | 111 | 2x600 | 380 | 16200 | 2x(p22 | 2x(pl6 | 1540 | 980 | 960 | 1340 | / | 900 | ||

| FAS-158 | 47.5 | 158 | 2x600 | cp550 | 380 | 16200 | 2xcp22 | 2x(pl6 | 1540 | 980 | 960 | 1340 | / | 900 | |

| FAS-180 | 54 | 180 | 2X780 | 380 | 20700 |

2x

|

2x

|

1840 | 980 | 1100 | 1640 | / | 900 | ||

| FAS-219 | 65 | 219 | 2x780 | 380 | 20300 | 2x(p28 | 2x(p22 | 1840 | 980 | 1100 | 1640 | / | 900 | ||

| FAS-270 | 81 | 270 | 3x800 | 380 | 34800 | 2xcp28 | 2x(f>22 | 2640 | 1030 | 1100 | 2440 | 1220 | 950 | ||

| FAS-328 | 99 | 328 | 3x800 | cp630 | 380 | 34200 | 2x(p28 | 2x(p22 | 2640 | 1030 | 1100 | 2440 | 1220 | 950 | |

| FAS-383 | 115 | 383 | 3x800 | 380 | 34800 | 2xcp28 | 2xcp22 | 3040 | 1030 | 1100 | 2840 | 1420 | 950 | ||

| FAS-455 | 137 | 455 | 4x800 | (p630 | 380 | 45600 | 2x(p35 | 2xcp28 | 3240 | 1050 | 1200 | 3040 | 1520 | 950 | |

| FAS-570 | 171 | 570 | 4x800 | 380 | 44000 | 2x(p35 | 2x(p28 | 3240 | 1050 | 1200 | 3040 | 1520 |

950

|

||

The high-quality air cooler is mainly composed of three parts: tube bundle, fan and frame (Figure 1). Tube bundles include heat transfer tubes, tube boxes, side beams and beams, etc. It can be arranged in three basic forms: horizontal, vertical and inclined top (herringbone) (Figure 2). Among them, the horizontal arrangement has a large heat transfer area, uniform air distribution, and good heat transfer effect; when the inclined roof is arranged, the fan is installed in the central space of the herringbone, which occupies a small area and has a compact structure. In order to offset the influence of the low heat transfer coefficient on the air side, a tube with fins on the outer wall of the light tube is usually used.

As a heat transfer tube, the finned tube can expand the heat transfer area. The finned tubes are arranged in layers, and their ends are connected to the tube box by welding or expansion. The pipes are generally 3 to 8 rows. Tube bundles are available in sizes up to 12 meters. The outer diameter of the light pipe is usually 25 mm and 38 mm, the height of the fin is generally 12 to 15 mm, and the width of the tube bundle is 100 to 3000 mm. The finned tube is the core element of the air cooler, and its form and material directly affect the performance of the equipment. The tube can be made of carbon steel, copper, aluminum and stainless steel; the fin material is determined according to the use environment and manufacturing process, most of which are industrial pure aluminum, and copper is also used in the case of high anti-corrosion requirements or special manufacturing process conditions or stainless steel. The fins can be arranged horizontally or vertically. The basic forms of finned tubes (Figure 3) are: wound type, insert type, rolled sheet type, sleeve type, welded sheet type, elliptical tube type, turbulent type (including spoke type, slotted type and corrugated type) Wait). The structure of the pipe box mainly includes flange type, pipe plug type and manifold type (Figure 4). Generally, the former is used for medium and low pressure, and the latter two are used for high pressure. In order to adapt to the thermal expansion of the tube bundle, one end of the tube box is not fixed, allowing displacement along the length of the tube. Fans usually use axial flow fans.

Ventilation

There are two types of ventilation: blast and induced draft. 1) Blow type: The air first flows through the fan and then flows into the tube bundle. 2) Induced air type: The air first flows through the tube bundle and then flows into the fan. The former operating cost is more economical, and the turbulent flow generated is beneficial to heat transfer, so it is used more. The latter has uniform airflow distribution, which is conducive to precise temperature control and low noise, which is the direction of development. The outlet temperature of the hot fluid is mainly controlled by adjusting the air volume passing through the tube bundle, that is, adjusting the inclination angle of the blades, the speed of the fan and the opening degree of the shutters. For fluids that are easy to condense and freeze in winter, hot air circulation or steam heating can be used to adjust the fluid outlet temperature.

Application

Air (wind) coolers are mainly used for traveling machinery (excavators, loaders, forklifts, cranes, combine harvesters, road construction machinery, construction machinery, etc.), and use air cooling to force the working