-

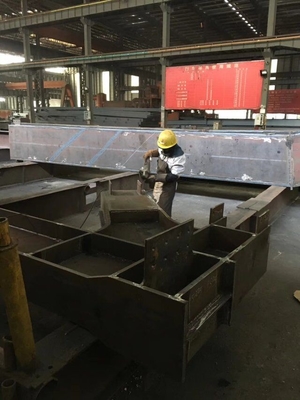

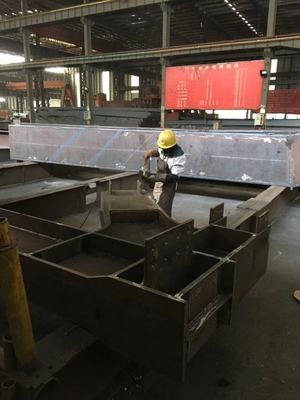

Structural Steel Fabrication

-

Heavy Steel Fabrication

-

Metal Steel Fabrication

-

Sheet Metal Fabrications

-

High Rise Steel Building Construction

-

Structural Steel Frame Construction

-

Steel Girder Bridge

-

Steel Truss Bridge

-

Pedestrian Overpass Bridge

-

Prefab Steel Frame

-

Light Steel Framing

-

Galvanized Steel Structure

-

Stainless Steel Fabrication

-

Steel Street Light Pole

-

Overhead Sign Structures

-

Steel Arch Bridges

-

Precast Girder Bridge

-

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job!

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job! -

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

Mid Rise Low Rise High Rise Steel Building Construction Mixed Multi Use Cold Rolled

| Place of Origin | Zhejiang, China |

|---|---|

| Brand Name | FASEC |

| Certification | ISO9001:2008, SGS, etc. |

| Model Number | OWN |

| Minimum Order Quantity | 1 pcs |

| Price | USD1000~USD2500 per ton |

| Packaging Details | Seaworthy packings into container or bulk vessel |

| Delivery Time | Based on client's needs |

| Payment Terms | L/C,T/T |

| Supply Ability | 600,000 tons per Year |

| Grade | , S355, Grade 300, ASTM A572 Etc | Dimensions | Costomized |

|---|---|---|---|

| Type | H-beam Column | Application | Residential Building |

| Surface Treatment | Galvanized | Place Of Origin | Hangzhou |

| Highlight | FASEC mid rise low rise Steels Constructions,FASEC mid rise low rise Steels Buildings Construction,mid rise low rise Steels Building Constructions FASEC |

||

Steel Framing Prefabricated Industrial Steel Buildings Quickly Assembled Construction

Building a high rise or any multi-level building demands the use of light-weight yet strong materials. Steel, by virtue of its high strength to weight ratio enables large spans and light weight construction. Steel structures can have a variety of structural forms like braced frames and moment resistant frames suitable to meet the specific requirements of higher buildings. Taller buildings also face higher wind loads, and hence steel being flexible, allows the building to move and deflect with the wind forces, rather than making it rigid like concrete.

| Material: | specification: |

| Length | As customer's requirement |

| Width | As customer's requirement |

| Height | As customer's requirement |

| Column | H shaped, S355, Grade 300, ASTM A572 etc |

| Beam | H shaped, S355, Grade 300, ASTM A572 etc |

| Purline | C/Z shaped,Q235/Q345 |

| Brace | Round bar,Q235 |

| Knee brace | Steel angle,Q235 |

| Tie bar | Steel round tube,Q235 |

| Roof panel | single steel sheet /sandwich panel/UPVC Panel |

Building tall with steel also allows more floors per total height of the building. This is due to the fact that the building structure in steel is lighter and more efficient, and has beams and that are not required to be as deep as those of concrete to support the floors. The ability to have lighter sections, allowing the same load bearing capacity per floor, allows space for almost 1.5 extra floors in the same overall external height of the building.

Pre-engineered steel systems, that are our specialty, allow further optimization and further efficiency in multistory steel building design. Delving into the mechanics of high rise building construction, we see that the introduction of hot rolled steel sections, using higher grade steel add more strength to the building. Better steel decking as a construction material brought about a revolution in the steel building space. Composite steel decking laid on each floor adds ability to transfer lateral loads more effectively through the structure aiding the structure to be stronger than conventional rigid materials. This added strength per floor allows the overall core steel structure to be lighter and even more efficient. High-rise frames are constructed of H-columns or box columns, (vertical-support members) and H-beams (horizontal-support members). Cross bracing or shear walls are used to provide a structural frame with greater lateral rigidity in order to withstand wind stresses.

![]()

![]()