-

Structural Steel Fabrication

-

Heavy Steel Fabrication

-

Metal Steel Fabrication

-

Sheet Metal Fabrications

-

High Rise Steel Building Construction

-

Structural Steel Frame Construction

-

Steel Girder Bridge

-

Steel Truss Bridge

-

Pedestrian Overpass Bridge

-

Prefab Steel Frame

-

Light Steel Framing

-

Galvanized Steel Structure

-

Stainless Steel Fabrication

-

Steel Street Light Pole

-

Overhead Sign Structures

-

Steel Arch Bridges

-

Precast Girder Bridge

-

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job!

Donald McwayneGood team members always offer budget in time and answer questions with patience, great job! -

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

Joseph AlexanderI am feeling fully respected when taking with Grace and she always gave the best advice. The first batch of the bridge panels got are great too. thanks all.

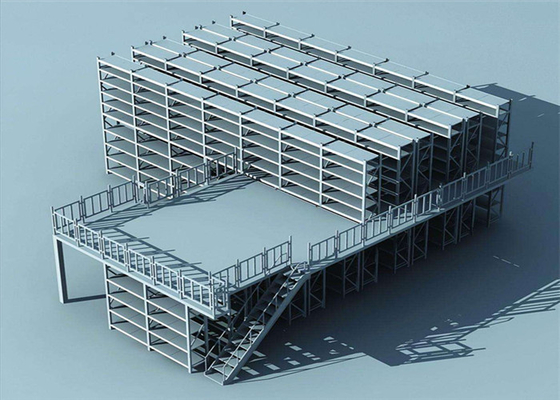

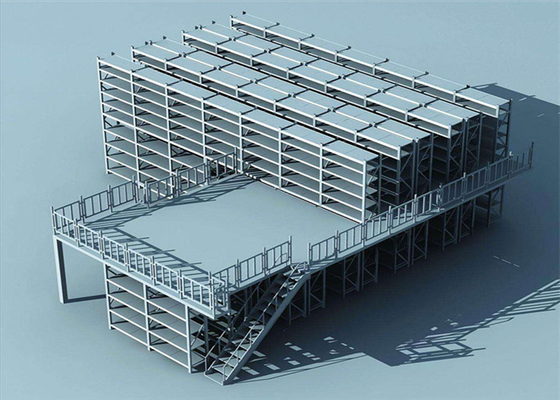

Lightweight Galvanized Steel Structure Building Greenhouse Frame Beams H Offshore Platform

| Place of Origin | China |

|---|---|

| Brand Name | FASEC |

| Certification | CE, ISO, SGS |

| Model Number | HZFS |

| Minimum Order Quantity | 10 tons |

| Price | USD1200-1800/ton |

| Packaging Details | Seaworthy packing in container or bulk vessel |

| Delivery Time | As per client's needs like 2-3 months |

| Payment Terms | L/C, T/T, D/A, D/P |

| Supply Ability | 100000 tons per year |

| Material | Steel | Grade | AS/NZS3678 G300, ASTM A36/A572, S275, Q355 Etc |

|---|---|---|---|

| Type | Heavy | Size | Customized |

| Surface Treatment | Galvanized Or Painted | Color | Customized Color |

| Application | Equipment Platform | ||

| Highlight | galvanized steel greenhouse frame,galvanized steel beams,galvanized h beam |

||

Galvanized Structural Steel Fabrications Marine Terminals Offshore Platform

The modern steel structure platform has various forms and functions, and its biggest feature is its fully assembled structure, which is flexible in design and can be designed and manufactured according to different site conditions. Structural platform. It is widely used in modern storage.

The composition and classification of the platform structure:

1. Composition: The platform structure is usually composed of paving, and the platform structure is usually composed of paving, primary and secondary beams, columns, and inter-column support, as well as ladder and railing primary and secondary beams, columns, and inter-column support, as well as ladders and railings.

2. Classification:

According to the requirements of use, it can be divided into indoor and indoor platforms, static and dynamic load platforms, production auxiliary platforms, and medium and heavy operating platforms.

The platform structure can be divided into:

1. A platform that rests directly on the tripod or corbel of the plant column. The function is usually a safe passage or a simple medium-sized operating platform.

2. One side is supported by the column of the factory building or the wall of the building, and the platform with the independent column on the other side.

3. Platform supported on large equipment.

4. All are independent platforms.

Platforms that are subject to heavy dynamic loads or equipment with high gravity should be separated from the plant columns and directly supported on independent columns.

Platform structure layout:

1. Meet the requirements of craft production operations, and ensure the clearance of traffic and operation. The general clear height should not be less than 1.8M, and the guardrail should be set around the platform. The height of the guardrail is generally 1M. When the platform height is greater than 2M, a skirting board with a height of 100-150mm should be set under the protective railing. The platform should be provided with ladders for up and down passage, and the width of the ladder should not be less than 600mm.

2. When determining the plane size, elevation, beam grid and column grid layout of the platform structure, in addition to meeting the requirements for use, the beam and column layout should also consider the position of the equipment load on the platform and other large concentrated loads and the large diameter industry Hanging of pipes, etc .;

3. The layout of the platform structure should strive to be economical and reasonable, and the transmission force should be straightforward. The arrangement of the beam grid should be compatible with its span. When the span of the beam is large, the spacing should also be increased. Make full use of the allowable span of the slabs and arrange the beams reasonably to obtain a better economic effect.

Specification:

| Steel Grade | Q235b, Q345b |

| Marerial | Galvanized steel |

| Width | 310-500mm |

| Thickness | 0.15-3.2mm |

| Weight coating | 30-275g/m2 |

| Application | All kinds of steel structure buildings |

![]()